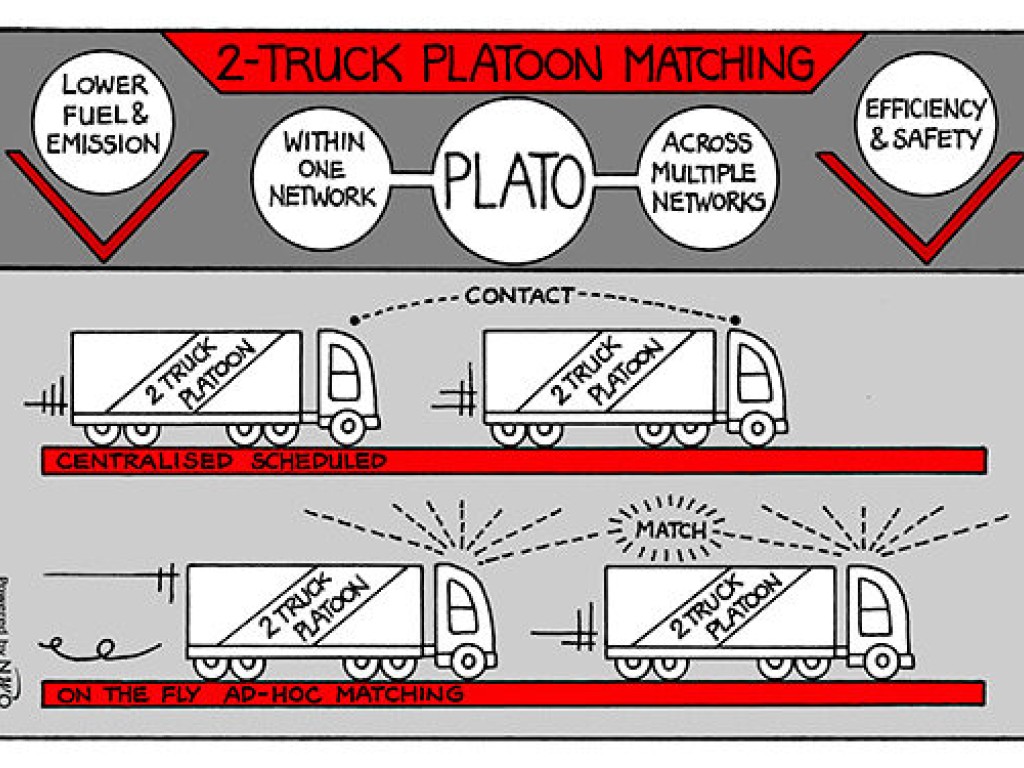

2-Truck Platoon matching for collaborative planning

In the project ‘2-Truck Platoon matching’ a business model is being developed for logistics service providers who want to do ‘platooning’ together. In 2-Truck Platooning two trucks drive right behind each other, less than a second apart. This can save a lot of fuel by both trucks, which reduces costs and is better for the environment. At the same time, in another project in the automotive sector the technology needed to be able to ‘platoon’ is being developed.

If you can have two trucks drive right behind each other, about 3/10 of a second apart, the second truck saves 10% fuel. That is good for the company and the environment. But the front truck also saves fuel. That has to do with aerodynamics: a truck creates a kind of vacuum behind the trailer due to its shape and length and that costs energy. In 2-truck platooning, that vacuum is removed by the second truck.

Before companies can start ‘platooning’ two things need to be developed. The vehicle technology and the collaboration model for logistics service providers, the business case.