Van Berkel Logistics explores automated truck planning with support MIT Innovation Broker Scheme

Van Berkel Logistics, with support from the MIT Innovation Broker Scheme of TKI Dinalog, has conducted a study on the potential of automated truck scheduling for container transport. The study was conducted by Squid.

Complexity in logistics planning increases

The logistics sector is under pressure due to a shortage of planners, growing volumes and an increase in last-minute changes. This also leads to challenges at Van Berkel Logistics: planners have less and less time for tasks such as coaching drivers or early detection of deviations. This has created a high dependence on individual planners, making the organisation vulnerable.

In addition, the focus in the current situation is mainly on completing orders within the time available. Consequently, goals such as efficiency, sustainability and capacity utilisation do not receive sufficient attention.

Technology as a supporting partner

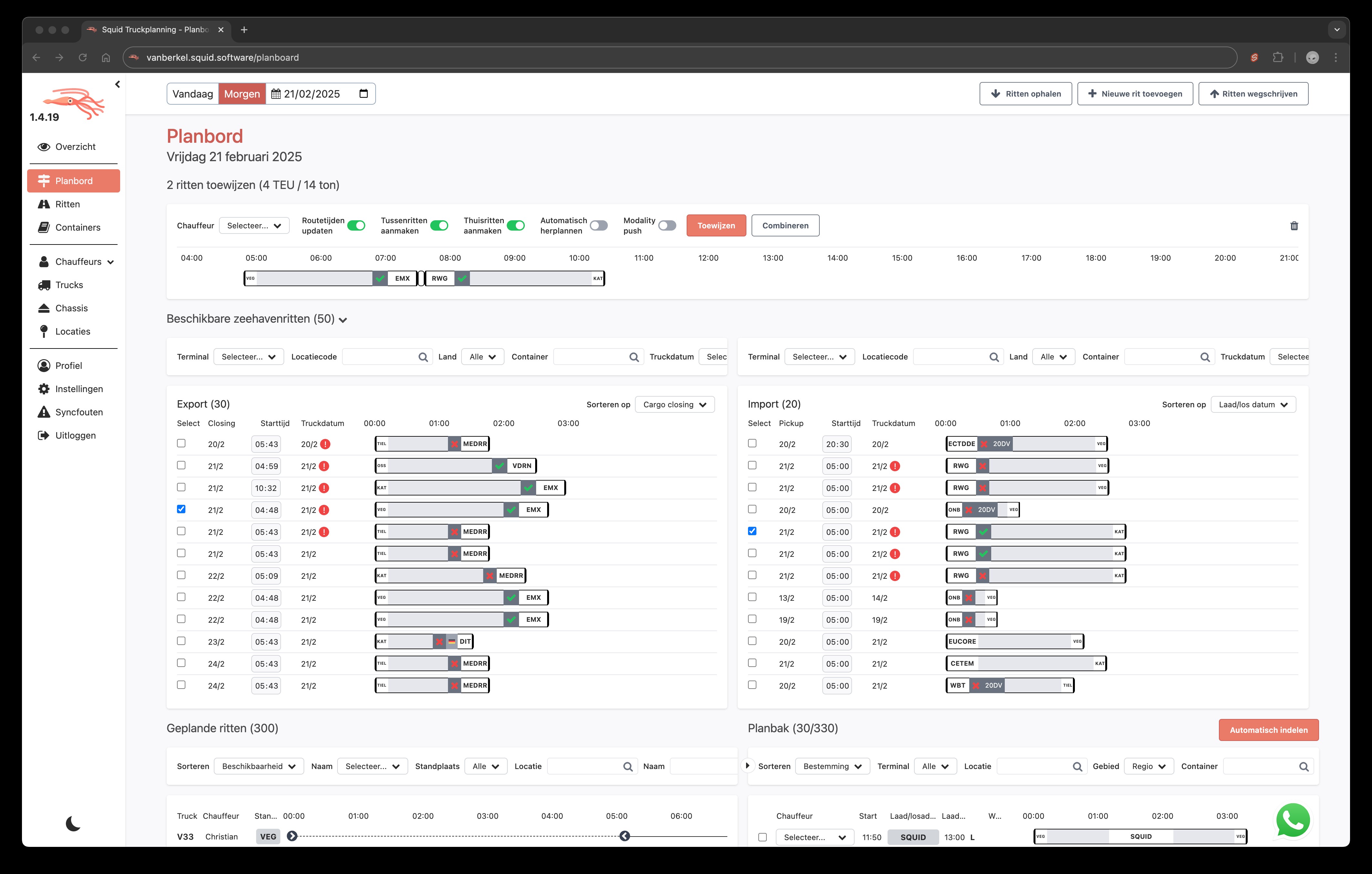

Van Berkel Logistics sees opportunities in digitisation of the planning process. The idea is that planners become less "decision-maker" and more "operator": they remain indispensable through their experience and customer orientation, but are supported by software that can calculate complex choices faster and better.

This can lead to:

reduced workload and increased job satisfaction for planners,

better utilisation of fleet capacity,

a higher level of service to customers,

and a more sustainable network through fewer empty kilometres and lower carbon emissions.

and a more sustainable network through fewer empty kilometres and lower carbon emissions.

Main insights from exploration

The study by Squid highlighted the steps needed to introduce automatic truck scheduling. Key recommendations are:

Stage-by-stage implementation: start with sub-processes and actively involve planners in development and set-up.

Improve information availability: link to existing systems (such as Modality and Data2Track) where possible and develop input screens for non-digital information where necessary.

Modular IT architecture: build adapters and interfaces so that software can be easily updated and extended, e.g. for future applications with electric trucks.

Gain user confidence: ensure user-friendly screens, good introductory guidance and an understanding of the algorithm's decision logic.

According to Squid, the success of automated truck planning depends heavily on the collaboration between humans and technology:

"Planners possess indispensable knowledge and experience. Software can support them by making complex calculations and scenarios understandable, so they can focus on the exceptions and the human side of the job."

Opportunities and challenges

Automatic truck planning offers many advantages, such as scalability when volumes grow, faster training of new planners and better control of KPIs. Software can also identify changes in planning faster and, in some cases, automatically reschedule.

At the same time, there are challenges, such as dealing with 'soft limits' (e.g. a container arriving just a bit too late), limiting algorithms' calculation time and ensuring user acceptance. In addition, explainability of algorithms is crucial for the trust of planners and customers: it must be clear why a decision was made and how parameters can be adjusted.

Squid and the future

Squid and the future

Squid has now been running in operations at Van Berkel Logistics for over two years. Initially, the focus was on digitising and visualising all the information a planner needs to make good decisions. It has since moved on to algorithms that automatically generate a basic schedule for work in the region. Work is also underway with Oxford University on an advanced seaport algorithm.

A key learning point from the past two years is that much 'soft information', such as customer and driver preferences, had to be recorded and digitised first. It has also become clear that a planner is not replaceable by an autonomous system: the power lies in automating standard work, so that the planner can focus on exceptions and intervene in time when the dynamics of logistics demand it.

Are you curious about how digital planning can contribute to more efficient and sustainable supply chains? Or would you like to know more about the approach and results of this project? Then contact TKI Dinalog.