CAMPI

For many complex capital goods, the costs of maintenance and (service) logistics represent a large fraction of the Total Cost of Ownership. Indeed, these costs are often much greater than the procurement cost. It is therefore essential that maintenance / logistics strategies be developed that minimize cost whilst maximizing the availability and security of assets. In the logistics industry preventive maintenance is often still the norm.

This project is innovative in many ways. Firstly, the benefits of data pooling and joint maintenance planning in a centralized control tower approach have been ill-researched, especially for advanced condition-based strategies. Secondly, logistics issues concerning the planning of parts, tools and personnel have been disregarded in the literature, despite being crucial for the success of maintenance strategies.

Thirdly, the above mentioned process industry characteristics concerning service logistics are taken explicitly into account. Fourthly, besides developing and testing coordinated planning methods, we also address cultural implementation barriers. Fifthly, proof-of-concept and scan tools will be developed in order to put knowledge to direct use, and stimulate partnering companies and the wider industry to pursue further optimization of coordinated maintenance and logistics activities in a control tower approach.

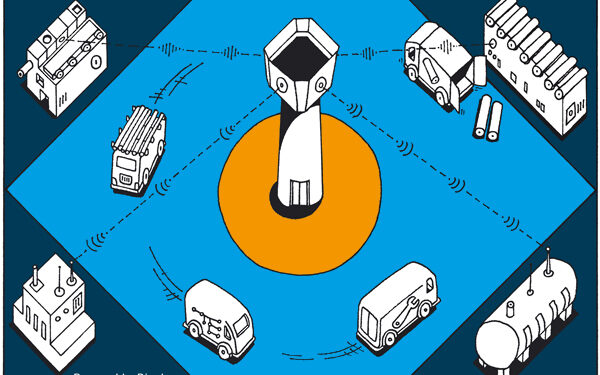

Control Tower approach

The main objective of this project is to continue the development of a control tower approach for maintenance and logistics planning in the process industries. The first two work packages examine the benefits of data pooling across disciplines and companies in the service supply chain, and of sharing maintenance/logistics resources and clustering operations. Work package III identifies (cultural) barriers and implementation issues for this type of coordinated approach.